POFIX GRAPHITE EPS

POFIX GRAPHITE EPS

POFIX THERM EPS foam boards are designed to be essential insulation components in various building structures. Manufactured from high-quality expanded polystyrene, these boards are intended for thermal insulation and specific applications where lightweight, versatile insulation is crucial.

Technical Details

POFIX THERM EPS

Expanded Polystyrene Foam Boards for Efficient Insulation and Versatile Building Applications

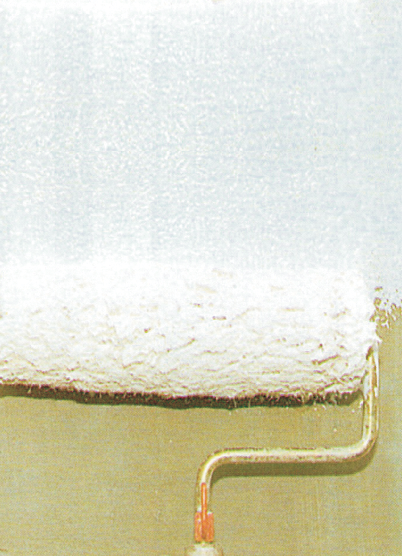

POFIX THERM EPS foam boards are designed to be essential insulation components in various building structures. Manufactured from high-quality expanded polystyrene, these boards are intended for thermal insulation and specific applications where lightweight, versatile insulation is crucial. The foam boards are applied seamlessly to the substrate, enhancing energy efficiency throughout the building. Key applications include:

- Efficient Insulation for Walls and Ceilings: Ideal for insulating residential and office buildings, schools, hospitals, and cold storage facilities, providing a barrier against heat loss and gain

- Floor Insulation: As a foundational layer, offering thermal insulation and comfort underfoot across various flooring applications

- Roof Insulation: Suitable for traditional, inverted, and green roof setups, ensuring top-down thermal efficiency and protection against the elements.

Usage

The optimal performance of POFIX THERM EPS foam boards is achieved when installed following our manufacturer’s guidelines, ensuring the boards are shielded from precipitation, wetting, or weathering during transport and storage. Installation must also comply with national building regulations for using EPS insulation materials.

| Technical Specifications | Parameters |

|---|---|

| length | 1250 mm |

| Nominal thicknesses | 10 mm to 1000mm |

| Nominal widths | 600 mm – 1000mm |

| Density range | 15kg/m3, 17kg/m3, 20kg/m3, 22kg/m3, 25kg/m3, and 30kg/m3 |

| width | 10 mm – 1000mm |

| Material | Expanded Polystyrene (EPS) is a lightweight, rigid, plastic foam insulation material produced from solid beads of polystyrene |

| EN and ISO standards to Product test | EN 826:2013; EN 1602:2013; EN ISO 11925-2:2010; EN 13501-1:2013; EN 12667:2001; EN 12939:2001; EN A1:2015 annex C; EN 12087:2013 (method 2A); EN 12088:2013; EN 12091:2013; EN 12088; EN 823:2013; EN 822:2013; EN 824:2013; EN 826:2013; EN 1605:2013; EN 1604:2013; EN ISO 4590:2016 (method) |

| |

|

| working life | at least 30 years |